|

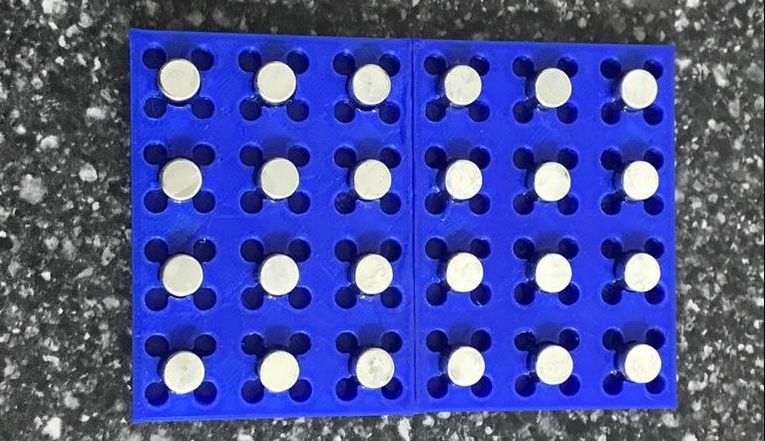

Upon the purchase of my 3D printer last year I have spent countless hours printing various board game pieces, and miniatures, but I hadn't actually got around to printing many useful items for my research. But now, the lab is now working on generating next generation sequencing libraries, and we have been borrowing much of the equipment from other labs. One piece of equipment, a plastic plate with strong neodynium magnets, is an essential component for bead purification clean-up steps. This seemingly inexpensive item sells for around $400 from the manufacturer, although it's really just some plastic and magnets. I did some snooping on Thingiverse.com and found this file for a 48-well magnetic bead separator plate - thanks to Ted Cybulski for uploading this design. I printed a single 48-well plate and purchased magnets (5/16" x 5/16") made of strong (N48) neodymium. I then affixed the magnets to my refrigerator one by one in the correct pattern, attaching the plate to make sure they are all in the perfect orientation. Next I applied a small amount of 2-part epoxy into each of the magnet slots and placed the plastic plate over the magnets on my refrigerator. I left it this way overnight to allow the epoxy enough time to cure, before removing it. Note that simply placing the magnets in the plastic plate will not work because their magnetic force is so great that they will fly right out. Also, these magnets must be treated with extreme care, as they may interfere with electronic devices (even at a seemly safe distance), and they tend to violently seek out metal to attach to. Finally, with magnetic plate in hand, a test trial was done and it was quite effective.  Finally, I reprinted two of the 48-well plates, assembled them individually as mentioned above, and then applied the 2-part epoxy generously between the surfaces of the two plates. I sanded each surface with a very fine-grain sand paper in order to ensure an even contact.

In all, this 96-well plate cost about $8 in magnets and plastic filament and took a few hours of printing time and assembly.

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

AuthorJordan Brock Archives

November 2019

Categories |

RSS Feed

RSS Feed